High-resolution photos with integrated notes show the respective working steps for the most common models on the vehicle market. Body and paint shops as well as workshops not dealing with this type of tasks at their daily work will particularly benefit from the easy-to-understand step-by-step instructions.

ESI TRONIC 2.0 2015 SOFTWARE

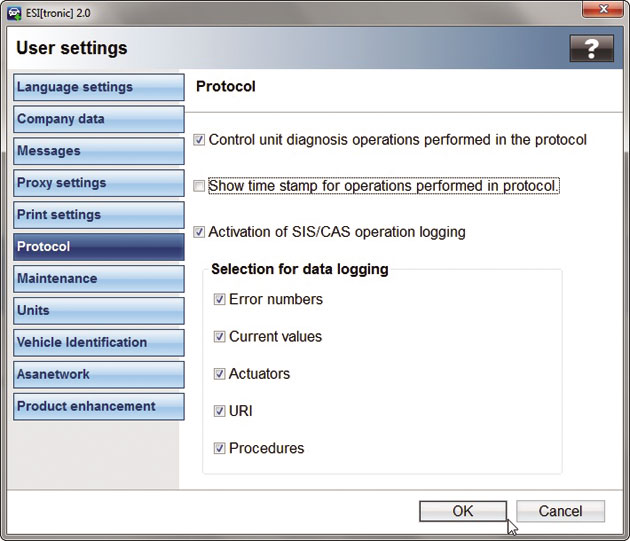

Step-by-step instructions for the assembly and disassembly of vehicle componentsĪssembly and disassembly instructions of components inside the vehicle and on its exterior – including lighting devices, operating and display units as well as sensors – have now also been integrated into the ESI software package. In the same manner, values recorded during a test drive can later on be reproduced and reconstructed at the workshop. This protocol can then be printed out for the customer.

Bosch ESI automatically records all of the individual steps of the diagnosis.

ESI TRONIC 2.0 2015 CODE

Moreover, the error code leads directly to additional diagnostic of repair instructions. With just one click, this allows the mechanic to compare the measured actual values with the respective target values. The direct linkage of target and actual values is yet another novelty. Maintenance schedules, for instance, are directly linked to the required diagnostic steps and to the reset of the service-interval indicator at the respective control unit.

Once the vehicle has been identified, the workshop software ESI purposefully supplies the mechanic with any required data and information for the respective service or repair task to be performed. Vehicle identification can be done, for instance, by means of the KBA code of the German Federal Motor Transport Authority or by the Vehicle Identification Number VIN.

0 kommentar(er)

0 kommentar(er)